Rexel

Key features:

– Cutting room table SK-3/AIR with air blowing tabletop creates an air cushion over which the spread fabric floats in order to be moved easily.

– Table frame and tabletops are built on the same sturdy structure of the basic SK-3 table.

– Tabletops are modular, up to 2,6 m long (8.5 ft) each section equipped with air pump.

– Table is equipped with control cabinet with separate switches for each blowing section.

Spreading machine UL-3 is a very simple and effective system for fabric spreading in comparison with all other possible technologies.

Equipment includes:

– The cutting table construction with fluent height regulation;

– The table with aluminum edges. Width of table may be customized to client’s specifications;

– The unwinding trolley;

– The clamping line;

– The end cutter with layer counter.

The knife mounted on the cutting table is designed for cutting fabric pieces to identical lengths and stacking them one-on-another fast and easy.

SK-3 cutting table is basic cutting room equipment in tailors’ and upholsterers’ shops. The modern and revamped construction was presented for the first time at the “INTERMASZ” fair, March 2008. The whole construction is made of a closed steel frame ensuring proper durability and stiffness. The work-top made of 25 mm thick coated board with edges finished with aluminum angles also guarantees long- lasting durability. Steel powder coating adds to the elegant look of the whole construction. The SK-3 cutting table consists of modules and can thus be quickly and easily extended at any time. You can also adjust the table height (to some extent) and level it using adjusting screws. The UL-3 spreading machine is optionally integrated into the SK-3 cutting table and is used for multi-layer fabric spreading on the work-top.

After the fabric reel is folded, the machine can be operated by one person. With an in-built fabric end cutter, every unfolded fabric layer can be automatically cut off. The SK-3 table with the UL-3 spreading machine greatly facilitates everyday workflow in a cutting room and improves its performance without the need to employ more staff.

Options for additional payment:

– Spreading head with cradle / shelf to spread fabric from a bundle and de-creasing roller UL-3/KZ – 75 EUR net.

– Spreading head with de-creasing roller UL-3/Z – 47,5 EUR net

– Turnable spreading head UL-3/O (not compatible with UL-3/KZ) – 162,5 EUR net.

– Turnable spreading head + de-creasing roller UL-3/OZ (not compatible with UL-3/KZ) – 210 EUR net.

– Fabric end cutter wire extension system (20 EUR net / meter).

– Bottom shelf for roll storage (37,5 EUR net / meter of table), shelf thickness 18 mm, finished with white PCV.

– Additional rod for thin cardboard cores ½ inch – 62,5 EUR net.

– Air-blowing: 625 EUR net for each 2,5 m section.

Available lenghts: 2,8m, 3,9m, 5m, 6,1m, 7,2m, 8,3m, 9,4m, 10,5m, 11,6m, 12,7m, 13,8m, 14,9m, 16m.

Width: 1,83m.

SK-3 cutting table is basic cutting room equipment in tailors’ and upholsterers’ shops. The modern and revamped construction was presented for the first time at the “INTERMASZ” fare, March 2008. The whole construction is made of closed steel profiles ensuring proper durability and stiffness. The work-top made of 25 mm chipboard with edges covered with aluminum angles that guarantee durability. Steel powder coating adds the elegant look of the whole construction. The SK-3 cutting table consists of modules and can be quickly and easily extended at any time. You can also adjust the table height (to some extent) and level it using adjusting screws.

Specifications:

Standard width of table: 1,83 m – 2,07 m.

Height of cutting table: 90 cm.

Each following section increases the cutting table by: 1,1 m

SK-3 cutting table is basic cutting room equipment in tailors’ and upholsterers’ shops. The modern and revamped construction was presented for the first time at the “INTERMASZ” fare, March 2008. The whole construction is made of closed steel profiles ensuring proper durability and stiffness. The work-top made of 25 mm chipboard with edges covered with aluminum angles that guarantee durability. Steel powder coating adds the elegant look of the whole construction. The SK-3 cutting table consists of modules and can be quickly and easily extended at any time. You can also adjust the table height (to some extent) and level it using adjusting screws.

Specifications:

Standard width of table: 1,83 m – 2,07 m.

Height of cutting table: 90 cm.

Each following section increases the cutting table by: 1,1 m

Available lenghts: 2,8m, 3,9m, 5m, 6,1m, 7,2m, 8,3m, 9,4m, 10,5m, 11,6m, 12,7m, 13,8m, 14,9m, 16m.

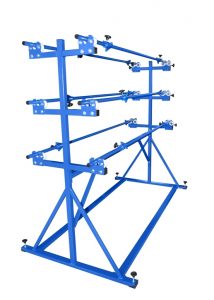

SK-3 cutting table is basic cutting room equipment in tailors’ and upholsterers’ shops. The modern and revamped construction was presented for the first time at the “INTERMASZ” fare, March 2008.

The whole construction is made of closed steel profiles ensuring proper durability and stiffness. The work-top can be made of 25 mm chipboard with edges covered with aluminum angles that guarantee durability. Steel powder coating adds the elegant look of the whole construction. The SK-3 cutting table consists of modules and can be quickly and easily extended at any time. You can also adjust the table height (to some extent) and level it using adjusting screws.

Specifications:

Frame made for the standard tabletop width of table: 1,83 m – 2,07 m.

Height of cutting table: 90 cm.

Each following section increases the cutting table: By 1,1 m.

Available lenghts: 3m, 4m, 5m, 6,1m, 7,2m, 8,3m, 9,4m, 10,5m, 11,6m, 12,7m, 13,8m, 14,9m, 16m.

Key features:

– Cutting room table SK-3/AIR with air blowing tabletop creates an air cushion over which the spread fabric floats in order to be moved easily.

– Table frame and tabletops are built on the same sturdy structure of the basic SK-3 table.

– Tabletops are modular, up to 2,6 m long (8.5 ft) each section equipped with air pump.

– Table is equipped with control cabinet with separate switches for each blowing section.

– Is equipped with fabric spreading head, lay end cutter and manual fabric clamp.

Key features:

– Machine is designed to automatically cut (through user input) pre-set length, and quantity sheets nonwoven fabric from rolls up to 350 kg.

– Cut panels are being fed onto the belt conveyor.

– Feed speed is 22m/min (72 ft/m).

– Feed speed is adjustable ±20%.

– Productivity for pieces 1000 mm long and 2000 mm wide (39”x78”) is 500 pcs/hour.

– Pneumatic clamp.

– Knife cuts in two directions.

– Blade sharpener.

– Custom machines available to accommodate different sized rolls.

– Control panel with durable buttons and touchscreen.

– Expanding airshaft with strips for cardboard core with material.

Specifications:

– Working pressure: 6 bar (87 PSI).

– Maximum roll width: 2500 mm (98,42”).

– Maximum roll diameter: 1100 mm (43,3”).

– Maximum roll weight: 350 kg (771 lbs).

– Overall width: 3540 mm (139,3”).

– Overall length: 5340 mm (210,2”).

– Overall height: 1845 mm (72,6”).

– Conveyor size: 2500 x 2500 mm (98.42”x98.42”).

– Frame made of steel with anodized aluminium profiles.

– Voltage: 230 V

– Power: 2,8 kW