Rexel

Cutting table REXEL US-1 is a modern, powerful and professional piece of equipment for roller blinds manufacturing.

Main advantages of the table:

– Depending on the needs, removable knife heads can cut fabric by ultrasonic or mechanical round knife.

– Touch screen panel provides easy and intuitive control, supporting languages: Polish, English and Russian.

– Fully automatic cutting process.

– Pneumatic clamping line provides even fabric pressure from the both sides of the table.

– Knife moving length during the cutting may be limited by the width of the material, thanks to the material sensor.

– Big illumination screen (260 mm width) is situated between the cutting line and material feed device.

– Precise length and angle measuring device is designed to regulate angles and length of the required fabric piece.

– Massive and strong table construction is made of powder coated steel profiles.

– It is possible to adjust height of the table using adjustment screws in the legs of the table.

– The table consists of the two pieces: cutting module itself and the post cutting module. There is a possibility of purchasing only cutting module and using it with the own cutting table.

Specifications:

– Total power ~ 900 W

– Power supply 230V/50Hz

– Clamping line working pressure 4 – 5 bar

– Ultrasonic knife moving speed 0,5 m/s

– Round knife moving speed 0,6 m/s

– Round knife speed 2500 rpm

– Knife replacing time 1 – 2 minutes

– Dimensions:

– Cutting module (LxWxH) 800x3700x1200 mm

– Post cutting module (LxWxH 2700x3200x950 mm

– Box dimensions 380 x 100 x 140 m

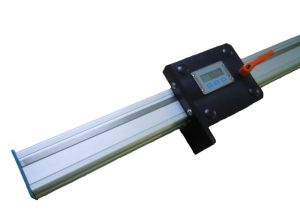

Is designed for fast and accurate length determination of the cut profile (e.g., pipes, rail, boxes, etc.),

equipped with a manual detent. The positioners are installed on a table with equipped tabletop.

Main advantages:

– Fast and easy movement of the detent mounted on an aluminum rail.

– Ability to set the stop in any position with the lever.

– Operating length up to 6 m (optional). Price for 3m length.

– All components are protected against filings.

– Lightweight and durable construction might be placed on the table surface.

– PR-1 – an electronic display which measures using a magnetic line, the measurement accuracy of 0.1 mm.

Is designed for fast and accurate length determination of the cut profile (e.g., pipes, rail, boxes, etc.),

equipped with a manual detent. The positioners are installed on a table with equipped tabletop.

Main advantages:

– Fast and easy movement of the detent mounted on an aluminum rail

– Ability to set the stop in any position with the lever

– Operating length up to 6 m (optional). Price for 3m length.

– All components are protected against filings

– Lightweight and durable construction might be

placed on the table surface

– PR-2 – measuring length on a guide profile.

We offer the perfect device for the fabric winding during the manufacturing roller blinds, indoor

blinds. This device allows winding the fabric on the tube in much faster and more accurate way unlike to

manual winding.

Main advantages of ZT-1

– Fast and simple installation and removal of a roller blind tube with the fabric after winding;

– Fabric winding unit can be used with a cutting table for roller blinds REXEL UK-1MAX, or with any other.

– Device is foot-controlled;

– Variable speed control;

– Suitable for most roller blind tubes;

– Intuitive machine operation.

Specifications:

Wattage: 120 W

Voltage: 230 V

Tube diameter: up to 40 mm

Tube length: up to 2650 mm

Rolling machine length: 3000 mm

On client’s order we will produce Roller blind fabric winding unit ZT-1 with required specifications.

Roller blinds inspection hoist WK-1 / Roller shades control lift WK-1.

The equipment is designed for testing of roller blinds. This control lift allows checking the levelness of slats in the blinds. Checking the blinds ensures that the fabric is properly winded on the tube and to make adjustments if necessary.

– Foot-controlled

– Fast and efficient inspection of the blinds

– Adjustable design for different size blinds

– Light and stong construction.

Specifications:

Power 0,4 kW 3x380V/50Hz (230V/50Hz optional)

Dimensions 3000x3000x500 mm

Guide maximum height 3000 mm (4000 mm optional)

Maximum width 2000 mm (3000 mm optional)

Slider’s speed approx. 0,3 m/s

Weight approx. 60 kg

Cutting table REXEL UK-1 ЕСО is designed for cutting roller blinds.

The equipment includes:

– Special cutting table with smooth tabletop.

– Pneumatic clamping line

– End-cutting knife

– Material feed device

– Measuring device.

The table has a massive steel structure that prevents any vibrations or deformations during operation. As an option it is possible to produce an illumination zone of any size. Maximum cutting length is 2.5 m. Knife operation is carried out from the remote control, lifting and lowering of the clamping line by lever. Constant blade speed is 0.5 m/s and there is no possibility of installing an ultrasonic knife at this table.

Specifications:

Cutting width: 2500 mm

Table width: 2670 mm

Table length: 2920 mm

Overall table witdh: 3280 mm

Overall table length: 3170 mm

Table height: 890 mm

Blade speed: 0,5 m/s

Knife rotation speed: 2300 rpm

Blade diameter: 108 mm

Power: 230 V

Wattage: 240 W

ATTENTION! This equipment is not available at once. It may be ordered after a thorough discussion of the customer’s needs. Time of production of the table is 7-10 days.

Maximum cutting length: 2 500 mm

The equipment includes:

– Cutting table length 3300 mm, width 2770 mm;

– End cutter knife;

– Pneumatic clamping line;

– Material feed device.

On this table you can cut:

– Fabric for the production of roller blinds;

– Different solid, thick tissues, felt;

– All kinds of textile products: carpets, rugs, runners, mats, floor coverings.

Cutting table for roller blinds consists of very rigid steel structures made of closed steel profiles. The working table top is made of laminated 25 mm chipboard. The table is protected by white powder coated aluminum edges on the perimeter. With the help of special screws you can adjust the height of the table and align the table horizontally. The cross-cutting knife attached to the working table top. The advantage of this end cutter is that through the thick material cutting is just a thin blade, not the leg of cutting knife.

Pay attention to the energy consumption of this machine: the motor that drives the circular blade is used for moving the end cutter device on the guide (1 motor performs two functions). Another advantage is the absence of idle, (process of cutting takes place in two directions). Pressing a button EMERGENCY STOP on the control box at any time you can stop end cutter e.g. to change the direction and continue cutting.

The equipment includes pneumatic clamping line, which will provide a strong and stable pinning the

cut material. You can adjust the clamping line by using the joystick. Working air pressure for the clamping

line is 3-5 atmospheres.

The equipment includes:

– Cutting table 3600 mm length, 2770 mm width.

– End-cutting knife.

– Pneumatic clamping line.

– Tabletop lighting.

– Material feed device.

On this table you can cut:

– Fabric for the production of roller blinds;

– Different solid, thick tissues, felt;

– All kinds of textile products: carpets, rugs, runners, mats, floor coverings.

Cutting table for roller blinds consists of very rigid steel structures made of closed steel profiles. The working table top is made of laminated 25 mm chipboard. The table is protected by white powder coated aluminum on the perimeter. With the help of special screws you can adjust the height of the table and align the table horizontally. The end-cutter knife is attached to the working table top. The advantage of this end-cutter is that while cutting through the thick material goes just a thin blade, not the leg of cutting knife.

Pay attention to the energy consumption of this machine: the motor that drives the circular blade is used for moving the cut-off device on the bus (1 engine performs two functions). Another advantage is the absence of idle, (process of cutting takes place in two directions). Pressing a button on the control box at any time you can stop end-cutter e.g. to change the direction and continue cutting.

The kit includes pneumatic clamping line, which will provide a strong and stable fixation of the cut material. You can adjust the clamping line by using the joystick. Working air pressure for the clamping line is 3-5 atmospheres.

ATTENTION! This equipment is not available at once. It may be ordered after a thorough discussion of the customer’s needs. Time of production of the table is 7-30 days.

REXEL Company is a leading manufacturer of blinds cutting tables in Poland. Our long experience in blinds cutting tables manufacturing allowed us to create the perfect table for blinds cutting.

REXEL UK-2 it’s the second generation cutting table, using it one can produce blinds faster and simpler! Table construction is made of closed, high quality steel profiles with powder coating which provides longstanding and protection against corrosion for a very long time. Tabletop edges protected with white powder coated aluminium angles; this solution provides impressive tabletop durability. Brand new mechanical knife construction with high speed electrical motor helps to achieve very accurate fabric cut.

Table UK-2 can cut roller blinds fabric from rolls up to 3000 mm width. Tabletop illumination zone is an additional option that helps to inspect blinds fabric before cut.

Standard widths of post cutting table after cutting line are: 3100 mm, 3400 mm, 4000 mm

ADVANTAGES & SPECIFICATIONS:

– Control panel with durable buttons;

– Tabletop illumination zone for fabric inspection;

– Improved manual positioner for 90º angle set;

– Pneumatic clamping line;

– Table is completely made of European materials;

– Energy chain for cutter cables protection;

– Two direction cutting ability;

– Round blade sharpening device;

– Cutting length: 3000 мм;

– Round blade speed: 4200 rpm;

– Head moving speed along guide: 0,9 m/s;

– Voltage: 230 V /1 phase / 50 Hz;

– Overall power: 700 W.

Key features:

– One can replace cutting head (ultrasonic or mechanical round knife) depending on fabrics type.

– Easy and user-friendly operation is achieved through touch-screen (available languages – Polish, English, French or Russian and Spanish).

– Partially automated cutting process,

– Pneumatic two side fabric clamp (in standard is supplied with rope pull switch along operator’s side of table).

– Fabric end sensor ensures faster cutting cycle – knife cart stops automatically after fabric piece is cut and returns back to start position.

– Finger sensor from the rollers side prevents fabric clamp from pressing if foreign object placed under clamp.

– Big inspection light (260 mm / 10″ width) between fabric feed rolls and cutting line

– Precise measuring angle bar (angle and bar cart backlash adjustments can be made).

– Stable construction is made of powder coated steel.

– Manual fabric feed rolls, with manual centring system. Motorized rollers are available with remote control.

– Fabric clamp foot switcher in included in set.

– Adjust levelling using adjustable table feet.

Specifications:

Cutting width: 4000 (157.4″)

Tabletop width: 4200 mm (165.3″)

Tabletop length after cut-off line: 3100/3400/4000 mm (122″/133.8″/157.4″)

Whole width: 4750 mm (187″)

Whole length: 5200 mm (204.7″)

Tabletop height: 900 mm (35.4″)

Cutting speed: Min: 0.1 m/s – Max: 0.5 m/s (0.32-1.64 ft/s)

Blade rotation speed: 2400 rpm

Blade diameter: 65 mm (2.55″)

Voltage: 230 V

Wattage: 900 W

Ultrasonic knife: V

Sharpening device: V

Mechanical round knife: V

Fabric clamp: V – PT*

Backlighting: V – S*

Variable knife cart speed: V

Variable blade rotation speed: X

Roll manual centering system: V – S*

Fabric clamp foot switcher: V – S*

Semi-automatic fabric feed system: V

*PT – Pneumatic two-side

*S – Standard

Cutting table REXEL UK-2 ЕСО is designed for roller blinds fabrics cutting. The table has a massive steel structure that prevents any vibrations or deformations during operation. Maximum cutting length is 2.5 m. Knife operation is manual, lifting and lowering of the clamp by lever. Constant blade speed is 0.5 m/s. Table is based on REXEL OT-1/R manual lay-end cutter.

Specifications:

Cutting width: up to 3000 mm

Tabletop width: 3200 mm

Tabletop length after cut-off line: 3010 mm or longer

Whole width: 3400 mm

Whole length: 3290 mm or longer

Tabletop height: 900 mm

Cutting speed:

Blade rotation speed: 2300 rpm

Blade diameter: 108 mm

Voltage: 230 V

Wattage: 120 W

Ultrasonic knife: –

Mechanical round knife: Yes, manual

Fabric clamp: Manual

Screen: No

An automatic measuring stop is designed for cutting any profiles made of aluminum.

This machine is equipped with a stop, which is automatically set to the specified position after entering the required length of the cut profile of the on the touch screen. The end of the profile should be moved all the way to the stop and a segment can be cut. This equipment provides fast and accurate positioning.

The price is for cutting stand without saw.

Using this pneumatic table you can significantly improve both productivity and the quality of

furniture.

Lifting table with pneumatic drive. For general use in the upholstery industry, for manufacturing of

upholstered furniture.

– The height of the lifting table can be adjusted during the manufacturing process;

– The table is supported with a steel frame, pneumatic cylinder and control valve;

– The table is foot-controlled at both sides of the table;

– The table has a connection (output) for pneumatic devices

– After the table is cut off from the power supply, it is automatically blocked (if the power supply is cut off,

the table top will not drop);

– The table has a drawer for storing basic upholstery tools.

The table structure is made of steel. The pneumatic cylinder D125x600 is foot-controlled at both

sides of the table. Leverage raises the table top to a maximum height of 1280 mm and lowers it to 300 mm.

The particle board table top is covered with high-quality fitted carpet and furnished with stainless

steel slide blocks which help to move furniture pieces on the table as well as grounding electrostatic

charges. Prevention of electrostatic charges avoids the occurrence of sparks and fire.

Specifications:

Model: ST-3

Working pressure: 6 bar (87 PSI)

Tabletop dimensions: 2000 mm x 900 mm (78.74″ x 35.43″)

Pneumatic cylinder: D125x600

Minimum height: 320 mm (12.59″)

Maximum height: 1280 mm (50.39″)

Maximum load: 160 kg (352.74 lbs)

The Pneumatic turntable ST-4/B is designed for gluing, assembly, packaging furniture and its components.

The whole construction is made of a closed steel profiles ensuring proper durability and stiffness.

Steel powder coating adds an elegant look of the whole construction. The work-top made of 18 mm thick coated board and covered with 2mm thick stainless steel. The work top strengthened with four stabilizers at the bearings.

The whole mechanism, including pneumatics, protected by a steel folding curtain 1.5 mm thick and rubber sheets. Pneumatic elements are hidden inside the table on a special slider that prevents contamination of the mechanism and pneumatic details while gluing furniture.

Main advantages:

– Pneumatic tabletop blocking system: tabletop can be blocked in any of 12 positions with pneumatic cylinder underneath the tabletop.

– Work top covered with stainless steel remains clean a long time;

– Steel curtain provides a durable and reliable performance of the mechanism;

– Stainless steel tubes on the table top provide a minimal contact of furniture with the table surface;

Specifications:

Model: ST-4/B

Working pressure: 6 bar (87 PSI)

Tabletop dimensions: 1200 mm x 750 mm (47.24″ x 29.52″)

Pneumatic cylinder: D125x200

Minimum height: 500 mm (19.68″)

Maximum height: 820 mm (32.28″)

Maximum load: 90 kg (198.4 lbs)

Our long experience in manufacturing pneumatic lifting tables and close cooperation with the Polish

largest manufacturer of upholstered furniture allowed us to create the perfect table for gluing furniture.

The Pneumatic turntable ST-4 is designed for gluing, assembly, packaging furniture and its components.

The whole construction is made of a closed steel profiles ensuring proper durability and stiffness.

Steel powder coating adds an elegant look of the whole construction. The work-top made of 18 mm thick

coated board and covered with 2mm thick stainless steel. The work top strengthened with four stabilizers at

the bearings.

The whole mechanism, including pneumatics, protected by a steel folding curtain 1.5 mm thick,

which is powder coated too. Pneumatic elements are hidden inside the table on a special slider that

prevents contamination of the mechanism and pneumatic details while gluing furniture.

Main advantages:

– Work top covered with stainless steel remains clean a long time;

– Steel cover provides a durable and reliable performance of the mechanism;

– Steel tubes on the table top provide a minimal contact of furniture with the table surface;

– Table is manufactured by Polish producer with years of experience.

Specifications:

Model: ST-4

Working pressure: 6 bar (87 PSI)

Tabletop dimensions: 1200 mm x 750 mm (47.24″ x 29.52″)

Pneumatic cylinder: D125x200

Minimum height: 500 mm (19.68″)

Maximum height: 820 mm (32.28″)

Maximum load: 90 kg (198.4 lbs)

Using this pneumatic table you can significantly improve both productivity and the quality of

furniture.

Assembly table with pneumatic drive. For general use in the upholstery industry, for manufacturing

of upholstered furniture.

– The height of the assembly table can be adjusted during the manufacturing process;

– The table is supported with a steel frame, pneumatic cylinder, and an automatic drive

– The automatic drive is foot-controlled at both sides of the table;

– The table has a connection (output) for pneumatic devices;

– After the table is cut off from the power supply, it is automatically blocked (if the power supply is cut off,

the table top will not drop);

– The table has a drawer for storing basic upholstery tools.

Specifications:

Model: ST-3

Working pressure: 6 bar (87 PSI)

Tabletop dimensions: 2000 mm x 900 mm (78.74″ x 35.43″)

Pneumatic cylinder: D125x600

Minimum height: 320 mm (12.59″)

Maximum height: 1280 mm (50.39″)

Maximum load: 160 kg (352.74 lbs)

The table structure is made of steel. The pneumatic cylinder D125x600 is foot-controlled at both

sides of the table. Leverage raises the table top to a maximum height of 1280 mm and lowers it to 300 mm.

The particle board table top is covered with high-quality fitted carpet and furnished with stainless

steel slide blocks which help to move furniture pieces on the table as well as grounding electrostatic

charges. Prevention of electrostatic charges avoids the occurrence of sparks and fire.

DESCRIPTION:

Pneumatic turntable ST2/OK is designed for gluing, assembling, packing, upholstering of the furniture or textile materials. It is also perfect for cutting of the leather.

Tabletop is made of 25 mm chipboard covered with 10 mm thick PE (polyethylene) sheet. Tabletop is placed in powderpainted steel frame.

Specifications:

Model: ST-2/OK

Working pressure: 6 bar (87 PSI)

Tabletop dimensions: 1600 mm x 1000 mm (63.99″ x 39.37″)

Pneumatic cylinder: D125x230 400 mm (15.74″)

Minimum height: 400 mm (15.74″)

Maximum height: 780 mm (30.70″)

Maximum load: 90 kg (198.4 lbs)

Ask for more information!

REXEL Company is a leading manufacturer of the lifting tables for upholstery in Poland. Using this pneumatic table you can significantly improve both productivity and the quality of furniture. For general use in the upholstery industry, for upholstered furniture manufacturing.

– The height of the lifting table can be quick adjusted during the manufacturing process;

– The table is supported with a steel frame and pneumatic cylinder;

– The cylinder is foot-controlled at both sides of the table;

– The table has a connection (output) for pneumatic devices;

– After the table is cut off from the power supply, it is automatically blocked (if the power supply is cut off, the table top will not drop);

Main advantages of the lifting table for upholstery:

– Increases productivity of manufacturing;

– Increases quality of the furniture;

– Increases worker’s comfort (it won’t be necessary for worker to work on knees to upholster under the furniture);

– Takes the load off the employee’s spine;

– Very reliable and stable structure is made of steel profiles;

– Tested and approved by the leading Polish and foreign furniture manufacturers;

– Made in Poland.

Specifications:

Maximum lifting height: 1250 mm

Minimum height with table top dropped: 600 mm

Maximum lifting capacity: 70 kg

Working pressure:: 6 bar

Lifting speed: 15 cm/s

Occupied surface of the basis: 700×900 mm

Weight: 100 kg

Using this pneumatic table you can significantly improve both productivity and the quality of

furniture.

Lifting table with pneumatic drive. For general use in the upholstery industry, for manufacturing of

upholstered furniture.

– Main feature of this table is so called Height Positioning System: when one presses a pedal, the table starts to move, making about 2 seconds pause at a certain point of movement. Height of this pause can be adjusted on a regulation profile under the table. This solution allows operator to work each time at necessary, comfortable height and not waste any time for small adjustments of table’s height.

– Anti-bouncing brake system that helps to prevent the table from bouncing.

– Table is supported with a steel frame, pneumatic cylinder, and an automatic drive;

– Cylinder is foot-controlled at both sides of the table;

– Table has a connection (output) for pneumatic devices

– After the table is cut off from the power supply, it is automatically blocked (if the power supply is cut off, the table top will not drop);

– The table has a drawer for storing basic upholstery tools.

Specifications:

Model: ST-3/KP

Working pressure: 6 bar (87 PSI)

Tabletop dimensions: 2000 mm x 900 mm (78.74″ x 35.43″)

Pneumatic cylinder: D125x600

Minimum height: 320 mm (12.59″)

Maximum height: 1280 mm (50.39″)

Maximum load: 160 kg (352.74 lbs)

Using this pneumatic table you can significantly improve both productivity and the quality of

furniture.

Lifting table with pneumatic drive. For general use in the upholstery industry, for manufacturing of

upholstered furniture.

– The height of the lifting table can be adjusted during the manufacturing process;

– The table is supported with a steel frame, pneumatic cylinder, and an automatic drive;

– The automatic drive is foot-controlled at both sides of the table;

– The table has a connection (output) for pneumatic devices

– After the table is cut off from the power supply, it is automatically blocked (if the power supply is cut off,

the table top will not drop);

– The table has a drawer for storing basic upholstery tools.

The table structure is made of steel. The pneumatic cylinder D125x600 is foot-controlled at both

sides of the table. Leverage raises the table top to a maximum height of 1280 mm and lowers it to 300 mm.

The particle board table top is covered with high-quality fitted carpet and furnished with stainless

steel slide blocks which help to move furniture pieces on the table as well as grounding electrostatic

charges. Prevention of electrostatic charges avoids the occurrence of sparks and fire.

Specifications:

Model: ST-3/R MINI

Working pressure: 6 bar (87 PSI)

Tabletop dimensions: 1600 mm x 900 mm (62.99″ x 35.43″)

Pneumatic cylinder: D125x360

Minimum height: 320 mm

Maximum height: 1060 mm (41.73″)

Maximum load: 130 kg (286.6 lbs)

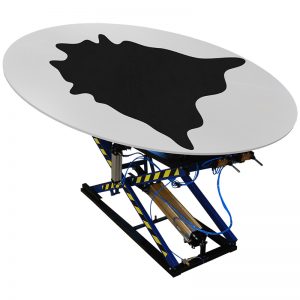

Table ST-3/OS is designed for leather cutting. Swivel tabletop has diameter 250 см and is made of laminated chipboard. Tabletop can be inclined at a 17° angle. This creates optimal working conditions during leather cutting – leather piece can be rotated without moving.

Key features:

– This solid construction is based on steel profiles and pneumatic cylinder.

– The pneumatic cylinder is foot-controlled.

– The table has a connection slot for pneumatic tools.

– After turning the table off it blocks automatically (cutting power off does not make the table fold).

– The table can be equipped with a drawer for upholstery tools.

– It has been proven that using our lifting tables decrease the use of energy by 15% in comparison to upholstery trestles.

– An increase in productivity of at least 14% has been observed when employees used our lifting tables instead of regular upholstery trestles.