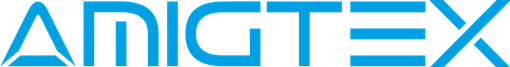

Cutting table for roller blinds UK-1 MAX

Maximum cutting length: 2 500 mm

The equipment includes:

– Cutting table length 3300 mm, width 2770 mm;

– End cutter knife;

– Pneumatic clamping line;

– Material feed device.

On this table you can cut:

– Fabric for the production of roller blinds;

– Different solid, thick tissues, felt;

– All kinds of textile products: carpets, rugs, runners, mats, floor coverings.

Cutting table for roller blinds consists of very rigid steel structures made of closed steel profiles. The working table top is made of laminated 25 mm chipboard. The table is protected by white powder coated aluminum edges on the perimeter. With the help of special screws you can adjust the height of the table and align the table horizontally. The cross-cutting knife attached to the working table top. The advantage of this end cutter is that through the thick material cutting is just a thin blade, not the leg of cutting knife.

Pay attention to the energy consumption of this machine: the motor that drives the circular blade is used for moving the end cutter device on the guide (1 motor performs two functions). Another advantage is the absence of idle, (process of cutting takes place in two directions). Pressing a button EMERGENCY STOP on the control box at any time you can stop end cutter e.g. to change the direction and continue cutting.

The equipment includes pneumatic clamping line, which will provide a strong and stable pinning the

cut material. You can adjust the clamping line by using the joystick. Working air pressure for the clamping

line is 3-5 atmospheres.